At Triplex, we focus almost exclusively on high purity fluid handling applications. The hallmark of any high purity process application is stainless steel. All stainless everywhere. Our tubing is stainless steel. Our pumps are stainless steel. Our gaskets are even impregnated with stainless steel so we can “detect” them. And the two most common grades of stainless steel we see are 304 and 316 SS. But how can we confirm that our material is what we say it is (especially if we specified 316)? Does the FDA just accept that it’s shiny and smooth and take the butcher’s word for it? No. No they don’t. That’s where Mill Test Reports (or MTRs) come in. So what is an MTR? Let’s dive deeper in today’s blog post.

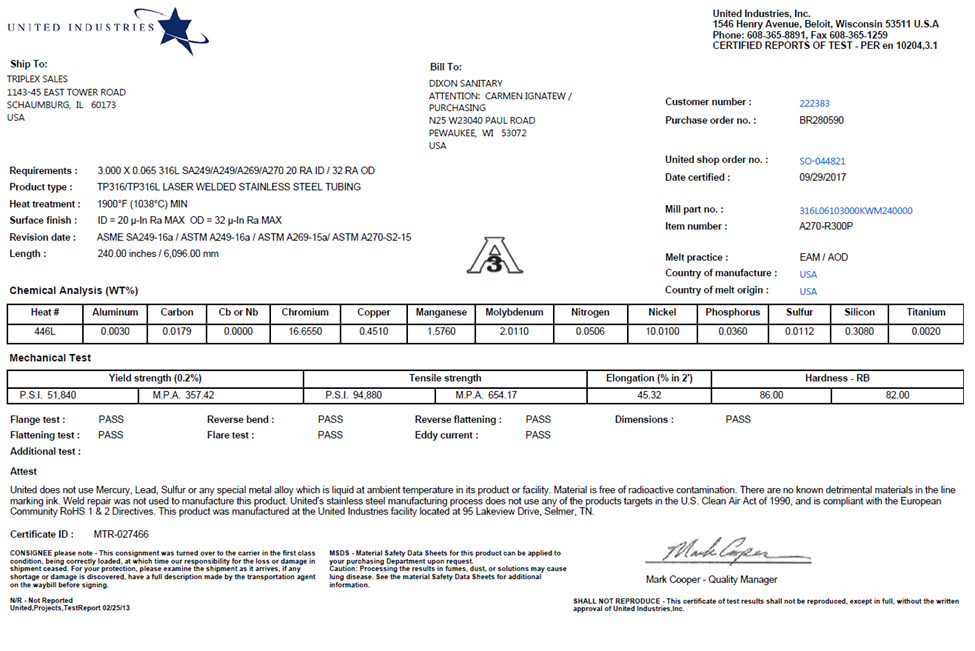

Anyone who has worked in the stainless steel industry is sure to have seen a piece of paper that comes with an inbound shipment. It’ll usually say something like, “Metallurgical Test Report” or “Material Test Report” at the top with a whole bunch of text below it. Well that text is actually the documentation from the mill of the specific chemical and physical properties of the product. Typically, an MTR will include most of the following information:

- Date

- Material Heat Number

- Material Grade

- Description

- Material Specification

- Heat Treatment (if any)

- Surface finish

- Shape or length

- Purchase order number

- Country of melt & manufacture

Here is an example of an MTR for some tubing we sold recently:

This document is important because using the MTR and the heat number off of the product, we can match the product to the MTR and confirm that the material or product received meets the project specifications. Certain applications require a specific grade of stainless (usually 316 or 316L) and the MTR is the proof that the material complies with the standard required for the application.

As you can see from above, we can even take it a step further and verify things like surface finish, elemental chemical composition, and additional physical properties such as yield strength ,tensile strength, elongation, and hardness. Using the heat number and MTR, we are able to tie the base stainless all the way back to where it was produced!

Because we appreciate how important documentation is at Triplex, as a standard practice, we include MTRs with all 316 fitting or tubing orders. We also keep electronic copies on hand in the event that the contractor or end user misplaces the hard copy MTR. Please note- mill test reports for 304 stainless steel are typically not provided or available.

It’s also important to note that Mill Test Reports are typically not provided with sanitary pumps or valves unless specified at the time of order and sometimes there is an additional charge. So if you know you’re going to need MTRs, be sure to ask on the front end. Working backwards is possible, but it’s a tedious and time consuming process unless you have a Niton analyzer (more on those in a future post).

So the next time you’re wondering if the fitting you’re holding is 304 or 316 stainless steel (no, you can’t tell just by looking at it), simply jot down the heat number and contact a Triplex Sales engineer today to help retrieve your Mill Test Report!